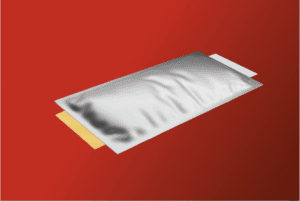

Customer requirement:

Our customer manufactures pouch cells for the automotive industry. In order to seal the sides of the pouch cell, he was looking for a sealing solution. This should be able to compensate for the layer jumps caused by sealing in the tabs.

In addition, the heat input on the packaged goods had to be low, since the seam is located directly on the cavity of the pouch cell.

Our solution:

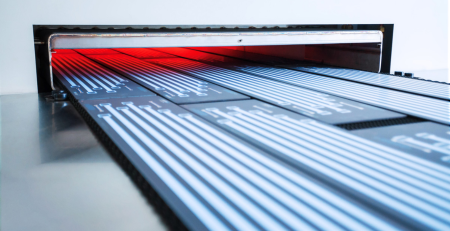

For this application, we have developed sealing tools that are heated on both sides and controlled with two control circuits.

The soft silicone pad under the heating bands compensates for the difference in height between the tab and the film, ensuring a consistently tight seam.

Thanks to the narrow heating band, the system heats up quickly and cools down again quickly. In addition, the heat input into the sensitive packaging material of the pouch cell is minimal and the unit can also be used in confined production spaces. In the first production step, the three sides of the pouch cell, including the tabs, are sealed together. Then the fourth side is sealed after degassing

Customer advantages:

✓ No warm-up phase of the system required, seam tight from the first cycle

✓ Repeatable sealing results from cycle to cycle

✓ Fast, precise control as no external sensor is required

✓ Minimal heat impact on the product

✓ Independent temperature control of each heatsealing band

✓ Fast heating and cooling of the system, due to the low mass of the heat-sealing band