IMPULSE SEALING

Technology to maximize your heat sealing speed and seam quality

✓ Create repeatable seam quality

✓ Minimize your machine down time

✓ Lower power consumption

✓ No heating-up or cooling-down times

✓ Minimal temperature entry on packaged goods

IMPULSE SEALING: Packaging solutions for all types of plastic films

The perfect solution for complex heat sealing applications.

Impulse sealing is a thermoplastic sealing process based on the generation of heat by electric current. A thin metal strip on the tool serves as a heating conductor.

The plastic is placed between the heated sealing tool and a counter part and joined together by the heat generated by the current pulses.

The pressure, temperature and time of the impulse are decisive parameters for achieving an optimum seam. This is monitored and controlled by a temperature controller. This process ensures a repeatable sealed seam quality and high machine output.

The perfect solution for complex heat sealing applications.

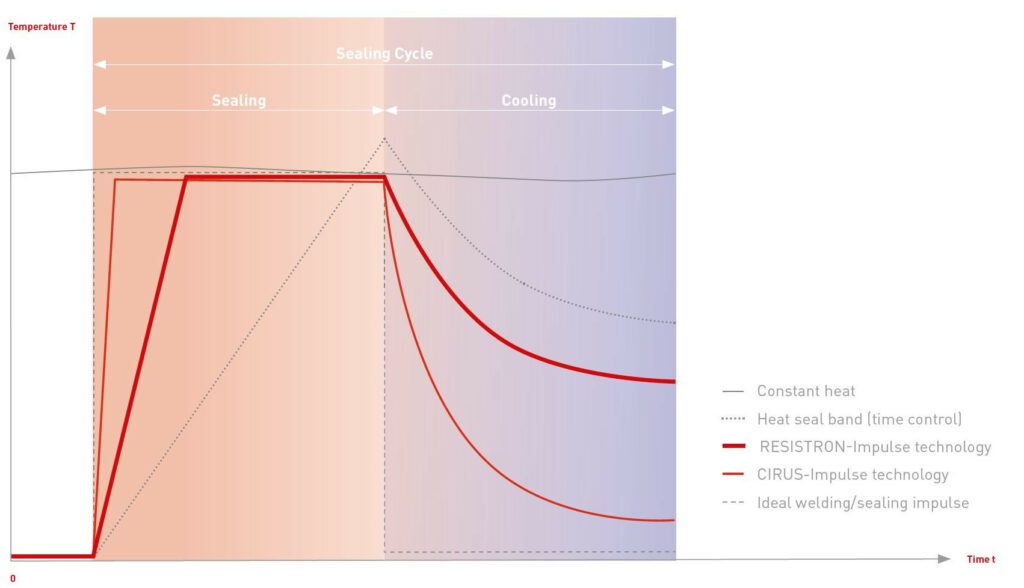

The optimum thermal profile describes a rectangular progression of rapid heating and cooling phases. Our ROPEX impulse technologies, RESISTRON and CIRUS, optimize heating in the best way possible.

Advantages of impulse sealing:

- Lower power consumption: Our ROPEX impulse technology minimizes energy consumption, which is both environmentally friendly and cost saving

- Consistent seam quality: The impulse sealing process guarantees repeatable, high-quality results that always meet the high quality standards of the end product

- High performance: Robust and durable, our tools handle heavy workloads with ease, resulting in optimized operations

- No waiting times: Our tools are ready for immediate use with no heat-up or cool-down phases, resulting in higher productivity and fewer delays

- Minimal temperature input: Impulse sealing limits heat transfer to packaged goods, which is ideal for heat-sensitive products and ensures their quality and safety

AREAS OF APPLICATIONS OF IMPULSE SEALING

Our solutions are used in a wide variety of industries and we look forward to implementing applications in new industries.

RESISTRON - HEAT SEALING BAND TECHNOLOGY

The tool is a sealing bar with a heat sealing band and a matching backing pad. For each application, we design the system individually to your requirements and create customer-specific solutions.

Technology overview:

- Active length almost without restrictions (about 7 m already realized)

- Active width almost without restrictions (about 40 mm already realized)

- 1D, 2D and 3D (Spout, tube etc.) possible

- Useful up to approx. 80 cycles per minute

- Suitable to layer jumps (flexible heat sealing band)

- Cooling of the seam possible

- Cut & Seal-applications with various solutions (cutting wire, beaded band, combination band, silicone profiles for cutting)

- Both sided heat possible (thick films, inserts between film layers, …)

CIRUS: HIGHLY DYNAMIC FILM SEALING SYSTEM

CIRUS is the perfect solution when it comes to film sealing applications with

- high temperature dynamics during heating and cooling of the sealing tool

- a complex seam or bag contour

- a low heat input into the packaged goods is permitted

The extremely high temperature dynamics are achieved by the special design of the tool: several layers of insulation are screen-printed onto a planar stainless steel substrate before the actual heating track is applied as a power resistor.

Technology overview:

- 1D and 2D possible

- Useful up to approx. 120 cycles per minute

- Partly suitable to layer jumps

- Ultrafast cooling of the seam (due to direct cooling of the heating line) possible.

- Cut & seal applications with various solutions (silicone profiles for cutting; cutting device)

- No movable parts

- Independence of format (due to direct cooling)

- Easy cleaning (maintenance-friendly)

- Humidity-resistant (FS-tools)

HEATSEAL BARS AND TOOLS

For RESISTRON and CIRUS heat- sealing solutions.

CONTACT US

We look forward to your e-mail request.