RESISTRON

HEATSEAL BANDS

We design and manufacture custom bands and tools for new projects to meet your exact requirements and project specifications.

CUSTOM CONTOURED HEATSEAL BANDS

The heat sealing band is the main component in the sealing process. A heat sealing band which is optimally adapted to the carrier design and the film properties is vital to the success of your impulse sealing system. Like ROPEX heat sealing bars, our heat sealing bands can be supplied in straight versions or with 2D or 3D contours.

Our possibilities are diverse: Whether-construction according to your design, fabrication of existing bands or optimization of the design for best sealing solutions. For new projects we design and manufacture customized contoured strips and tools according to your specifications.

Contours available:

- Open and Closed-Contours (simple to complex shapes)

- Precision large and miniature bands

- Surface mounted cutting wires (seal and cut your required shape)

- Precisely located fixture tabs and welded location pins

- Surface and identification marking

- Terminal options: inside/outside tabs (or both), surface sealded tabs, brass tabs

- Isolated heat zones, copper plated (zebra bands) and or welded zones

- Copper, or Copper + Nickel plated band tabs for improved heat seal band life

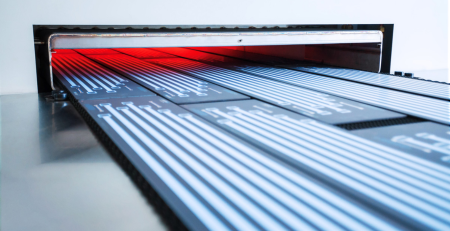

Straight heat sealing bands

Straight heat sealing bands (strips) are the most widespread.

Their thickness, width, profile, length and alloy vary according to the application. Heat sealing bands can have a thickness of 0.1 mm to 0.4 mm and are usually between 2 mm and 10 mm wide. The length ranges from a few centimeters to several meters.

The part of a flat band facing the film is generally wedge-shaped (tapered), to ensure that a sufficiently strong sealed seam is also created at the edges.

The design of the heat sealing band ends also varies considerably. A reliable connection must be guaranteed between the band and the bar end block. Easy handling and freedom from contact resistances are also important. Sleeves, eyelets and brass end pieces are used for this purpose.

Parts of the heat sealing bands that don’t need to be heated for sealing – especially the free ends – are passivated by suitable types of coating. This prevents them from overheating, which is also vital for precise temperature control.

Heat sealing bands play a functional role in the impulse heat sealing process, which means we – as the supplier – have no room to compromise on quality.

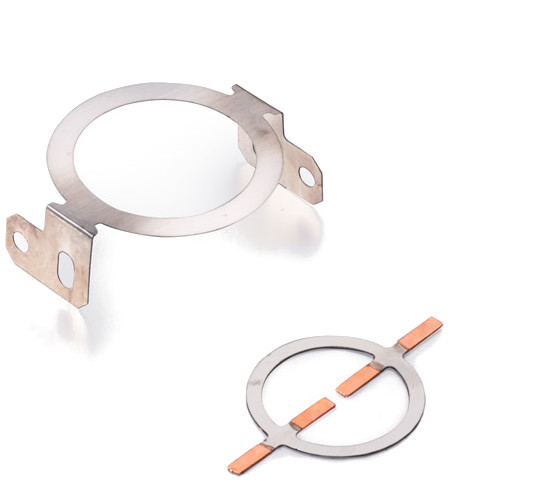

2D contours

The general description above is equally applicable to contoured heat sealing bands in 2D or 3D:

- The contour of the heat sealing band must be matched to the required seam and to the contour and geometry of the substructure.

- Bar end blocks and wedge-shaped edges are also required here.

- The ends of the heat sealing band should have a low-impedance coating of copper, silver or nickel.

- The electrical connections should be adequately sized to prevent measuring errors due to temperature rises when determining the resistance.

All contoured heat sealing bands supplied by ROPEX are designed using a 3D CAD tool. The files created in this way are used for further processing, e.g. laser cutting or anti-stick covers. The technical specifications are carefully documented and kept together with a reference sample, which can be used again for follow-up deliveries.

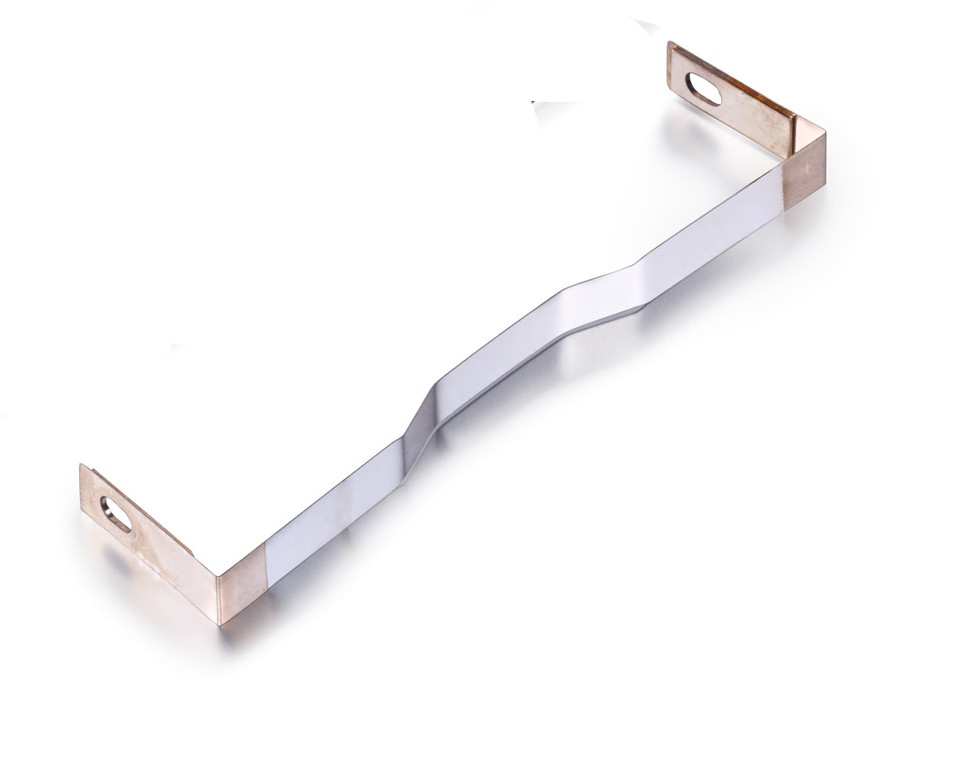

3D contours

Heat sealing bands can also be supplied with a 3D contour to match our sealing bars. This is necessary for sealing applications featuring a spout, for instance. The heat sealing band corresponds exactly to the contour of the closure. One particular challenge here is that instead of simply sealing the film, it must be sealed with a closure.

Contoured Heat Seal Bands

Options available:

✓ Open and Closed-Contours (simple to complex shapes)

✓ Precision large and miniature bands

✓ Surface mounted cutting wires (seal and cut your required shape)

✓ Precisely located fixture tabs and welded location pins

✓ Surface and identification marking

✓ Isolated heat zones, copper plated (zebra bands) and or welded zones

✓ Copper, or Copper + Nickel plated band tabs for improved heat seal band life

✓ Terminal options: inside/outside tabs, surface welded tabs or pins, … etc.

Customized version

Many applications require highly customized heat sealing bands. We can provide exactly the right solution – from bands with multiple temperature zones to circular heating tools. With our longstanding experience and our 3D CAD system, even the most complex geometries are not a problem.

QUESTIONNAIRE

With the following questionnaire we can calculate your application and create an application report.

For this purpose, please enter your contact data and parameters in the respective fields and submit the questionnaire. Based on your data we will create your application report and contact you in case of any queries.

ROPEX TOOLS AND CONSUMABLES

INDUSTRY SOLUTIONS

Our solutions are used in a wide variety of industries and we look forward to implementing applications in additional industries.

CONTACT US

We look forward to your e-mail request.