Customer requirement:

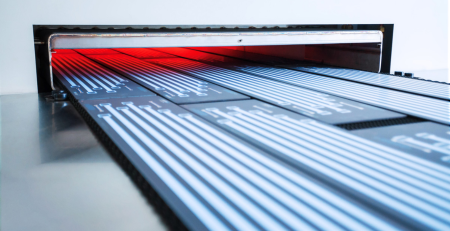

Using a sustainable, paper-based material with thermoplastic layer to safely package hygiene products and meet the production time specified by the customer.

In addition to the material used, the challenge was to generate a uniform heat input on the material and to meet the production time specified by the customer. Particularly in the side gusset area, it is necessary to compensate for the different layers of the material (4-2-4).

Our solution:

For this reason, we have developed a sealing bar heated on one side. We use a bar with a silicone profile as a counter-layer to compensate for the layer jumps and to produce a tight seal.

Thanks to the fast heating and cooling rates of the CIRUS technology used, we were also able to meet the process time specified by the customer.

Another highlight for the customer: Should he wish to seal plastic on this machine in the future, he will be able to use the same tools.

Customer advantages:

✓ Use of sustainable packaging material

✓ Changeover to paper without new tools

✓ Sealing of paper (Possible if corresponding thermoplastic layer like sealing lacquer, sealing glue, sealing coating).