new display controllers

Available in 2024!

RES-5200, RES-5400, UPT-6400

Highlights

- Graphical display of the measured values

- Recipe manager for up to 9 recipes

- TCR calculator: adjustment of the heat sealing band TC by means of reference value input

- CSA approval

QUESTIONNAIRE

With the following questionnaire we can calculate your application and create an application report.

For this purpose, please enter your contact data and parameters in the respective fields and submit the questionnaire. Based on your data we will create your application report and contact you in case of any queries.

Your advantages

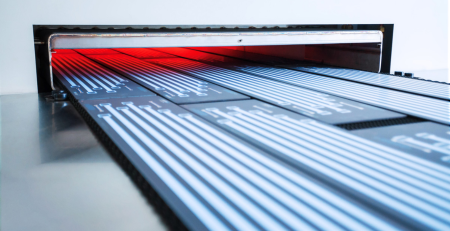

High flexibility in design

Different film formats

Sensorless temperature control

in ms range for highest repeatability

Higher cycle rates

due to cut & seal in one process step

Cost-effective

Compared to ultrasonic sealing

Digital Plug & play

Simple integration into the machine control system

Reproducibility

Defined heating zones

Instant stability of the seam

due to integrated cooling

You need a customized solution?

We will be happy to advice you!

THAT'S WHY ROPEX

Application specific solution

Risk reduction

Expert know-how

Detailed application report

CONTACT US

We look forward to your e-mail request.