Customer requirement:

Our customer produces two different types of medical pouches. Both are made of polyethylene film, but they differ in size and contour. Our customer’s request was to seal the two pouches efficiently on a single machine, in alternating sequence, and then to stamp them out.

Of extreme importance, was the ability to deliver a high-quality product, while also increasing the machine’s overall throughput.

Our solution:

All these requirements can easily be met with our ROPEX impulse sealing process. We developed a customized solution, based on our RESISTRON sealing system, to meet the specific needs of our customer.

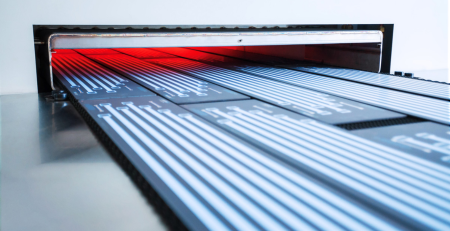

For each of the two pouches, we engineered an application-specific sealing tool with an integrated water-cooling system, and an independent control circuit. Two heating bands, each custom designed to the shape of the pouches, supply the heating impulse. The counter layer generates the required pressure on the seam in parallel.

In consultation with our customer and their system manufacturer, we designed the tools in such a way that they seamlessly fit into their system and can be easily changed. To increase the output, we integrated a water-cooling system. This feature allows the heating element to quickly return to its ambient temperature. The result not only improves production speed, but also creates a consistent, repeatable seal.

Customer advantages:

Our customer now benefits from having a customized sealing solution which allows their two products to be produced in alternating sequence, on just one system. If required, additional tools for further pouch designs can be flexibly integrated. The heating bands can be effortlessly replaced, when necessary. To ensure the traceability and repeatability (as often required in the medical sector), the heating bands are produced and supplied in single batches. Also, a temperature diagnosis function can be integrated into the machine control system, if desired.

With a customized RESISTRON Sealing System, our customer can now produce two different medical pouches, to the highest quality, on a single system.

The benefits at a glance

✓ Seal two different pouches on one machine

✓ Traceability and repeatability of heating bands due to single batches

✓ A strong, smooth seam

✓ A customized overall solution

✓ The very first bag is sellable

✓ Flexibility in materials and formats

✓ Easy maintenance

✓ A robust, reproducible process