Customer requirements:

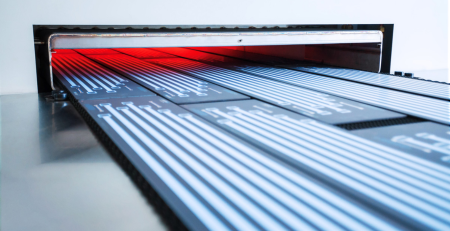

Our customer uses a degradable, water-soluble bio-film (PVOH) to package liquid detergents in an environmentally friendly way. Before creating the pods, two films are placed on top of each other and sealed at regular intervals along the longitudinal seam. For this seam, the manufacturer was looking for a tool that would guarantee him a high process speed and a stable seam.

Our Solution:

For the system design, we chose our RESISTRON impulse sealing technology. The application includes a sealing tool with a suitable counter-layer as well as a temperature controller.

With our solution, the film is fed evenly through the machine to create the pods in the next step.

The design challenge was to not overheat the delicate bio-film while creating a smooth and strong seam. Active temperature control allows the heat input to the film to be actively influenced, ensuring consistent quality with each impulse.

In addition, the customer reduces the risk of injury to his employees in the event of machine maintenance. Since the tools are heated exclusively during the impulse, there is no risk of burns during a tool change.

Customer Advantage:

✓ High employee safety – no risk of burns during a mold changeover

✓ Process stability

✓ A high-quality, smooth seam

✓ Active temperature control

✓ A customized overall solution

✓ Easy maintenance